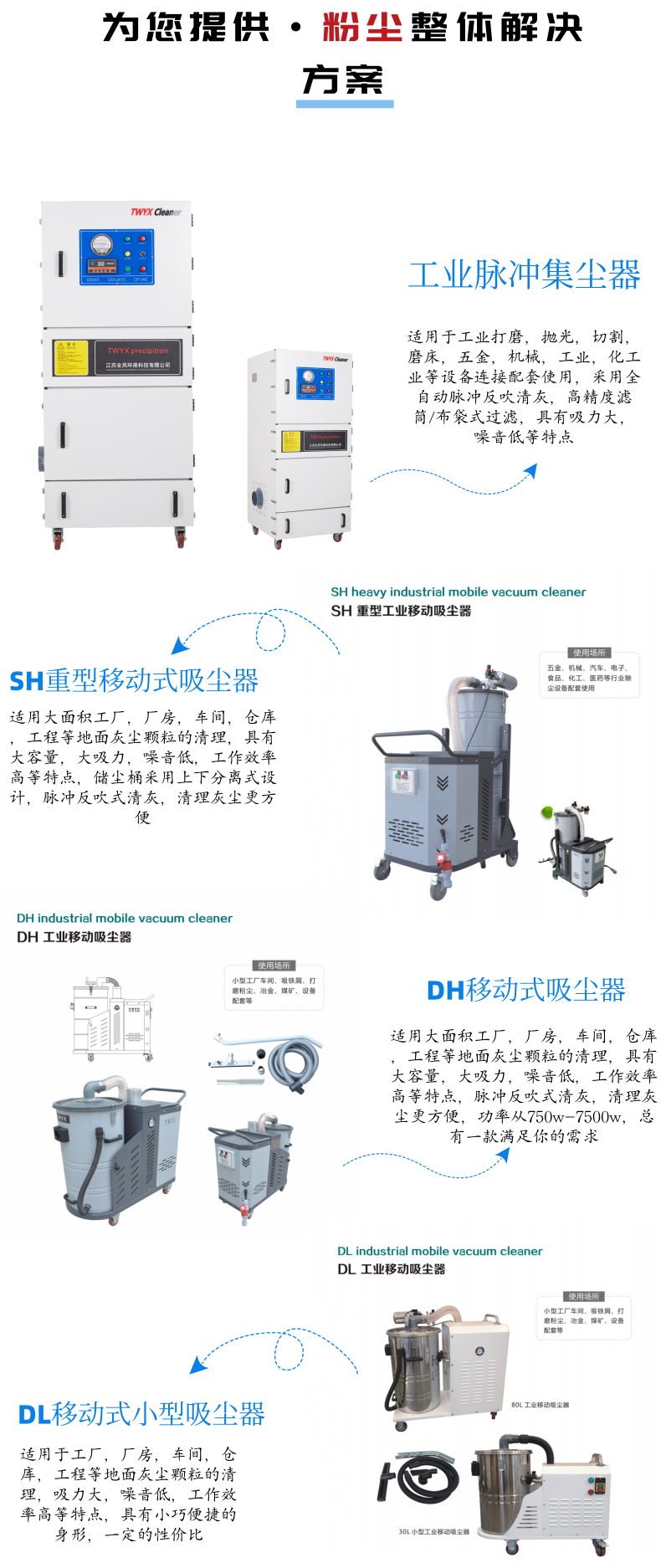

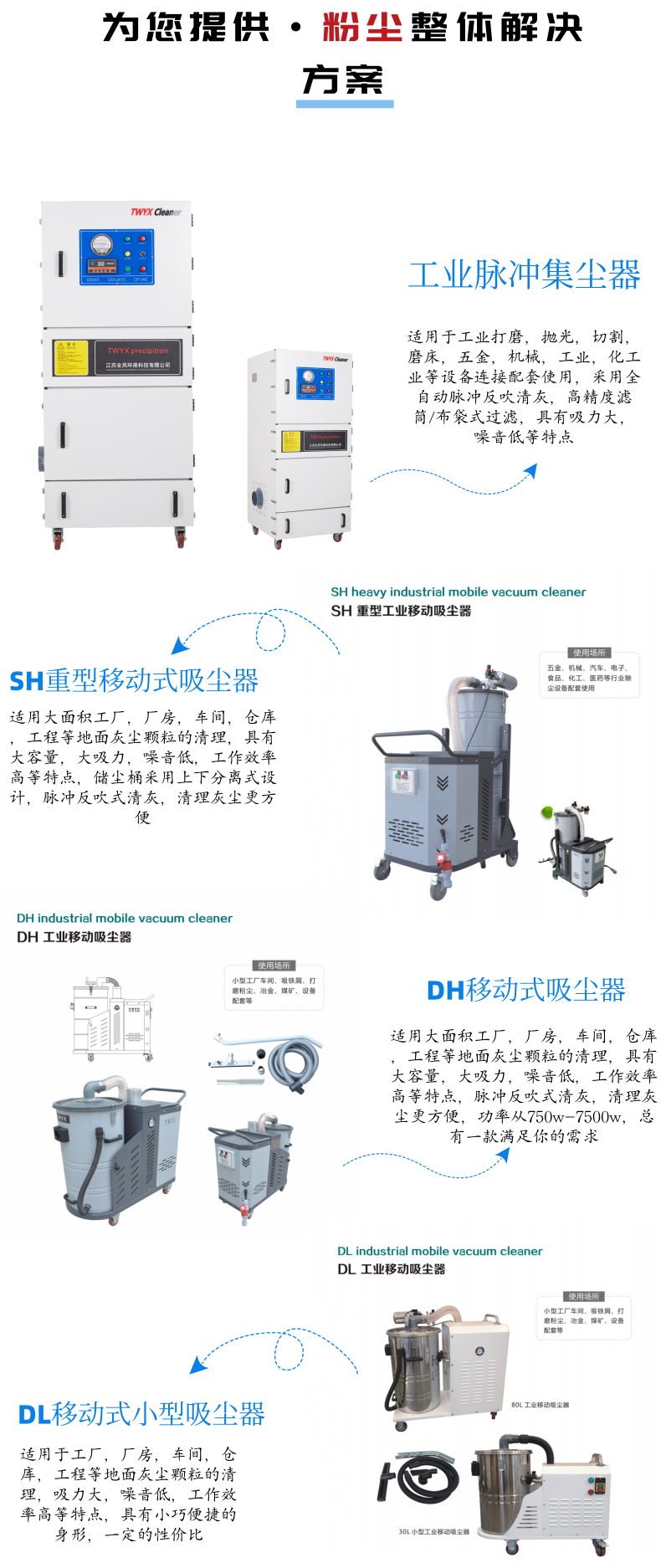

工业脉冲式布袋除尘器生产厂家 工业集尘器用于工业用途的收集吸取生产、操作、运输过程中产生的废弃介质颗粒物、粉尘烟雾、油水等的设备。工业吸尘器的优点主要是能耗低、噪音少、运作稳定、过滤、处理风量大、过滤精度好、滤筒清灰效果高,工业吸尘器采用交流电源,功率较大,一般分为 220V和380V两种,其工作原理是采用电机带动高压分机(或采用一体机)在有限容积内产生负压,从而产生吸力,介质物被吸入后,通过滤袋进行过滤或滤桶进行二级过滤,造纸行业:在纸品生产、切割过程中,清理各碎纸屑及灰尘,普通型只可以吸收含水量代的干型介质物,干湿两用型的可吸收加工过程中产生的油、水等。主机箱体内部附有吸音材料,降噪效果明显,可安装于任何场所,工业吸尘器加装排气管后可以用来吸掉生产操作过程中产生的烟雾、气体等。用于清理沉积的粉尘、渣块,特别是对锅炉的日常清扫,定期保养时的积灰清除。

The vertical combined structure is adopted, which is composed of push-pull drawer type dust storage, filter cartridge dust removal, pulse jet dust removal and air outlet. The dust collection effect is 99.5% in an economic way. The modular combined design can be determined according to the user space. The power of the dust collector ranges from 0.75 kW to 22 kW. It is equipped with a secondary filtration system. The advanced plunger explosion back cleaning system is applied to optimize the back cleaning and a variety of filter materials, It can be applied to the collection of various smoke and dust.

机器说明:

功率: 0.75kw~15kw

电压: 380V/50Hz 或 220V/50Hz

流量: 180m3/h~6000 m3/h

真空度: 1.6~70KPa

集尘桶容积: 30/200L

吸入口径: 32 、 40 、 50 、 75 、 100 、 125 、 150 、 200 (标配)或定制

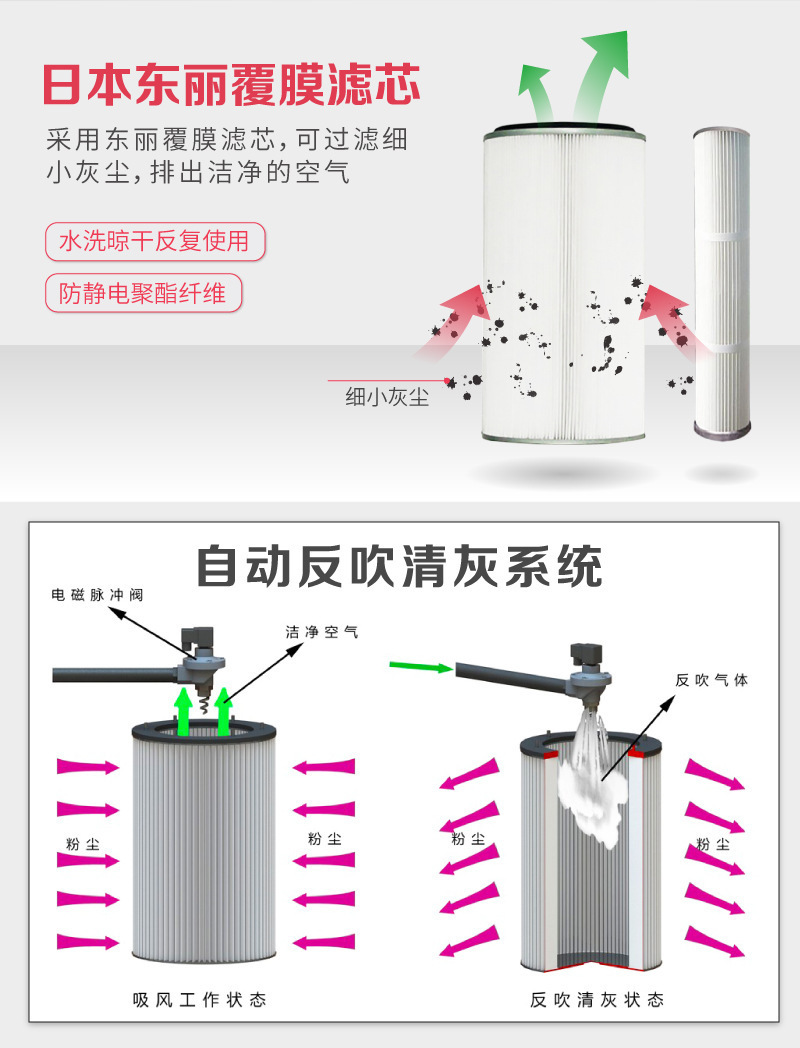

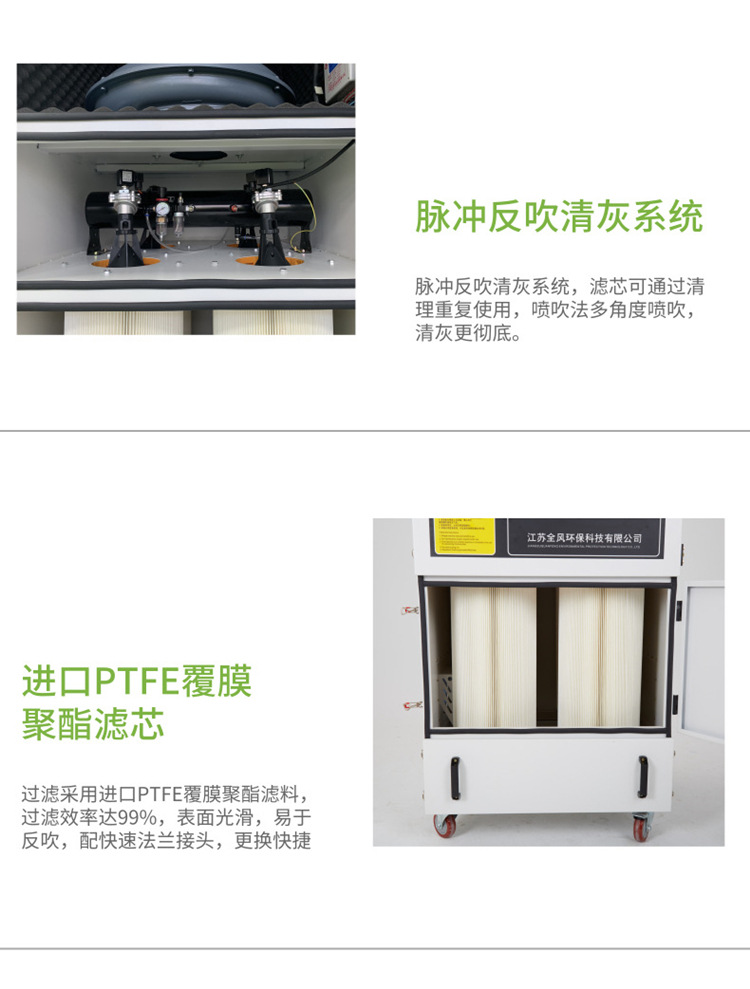

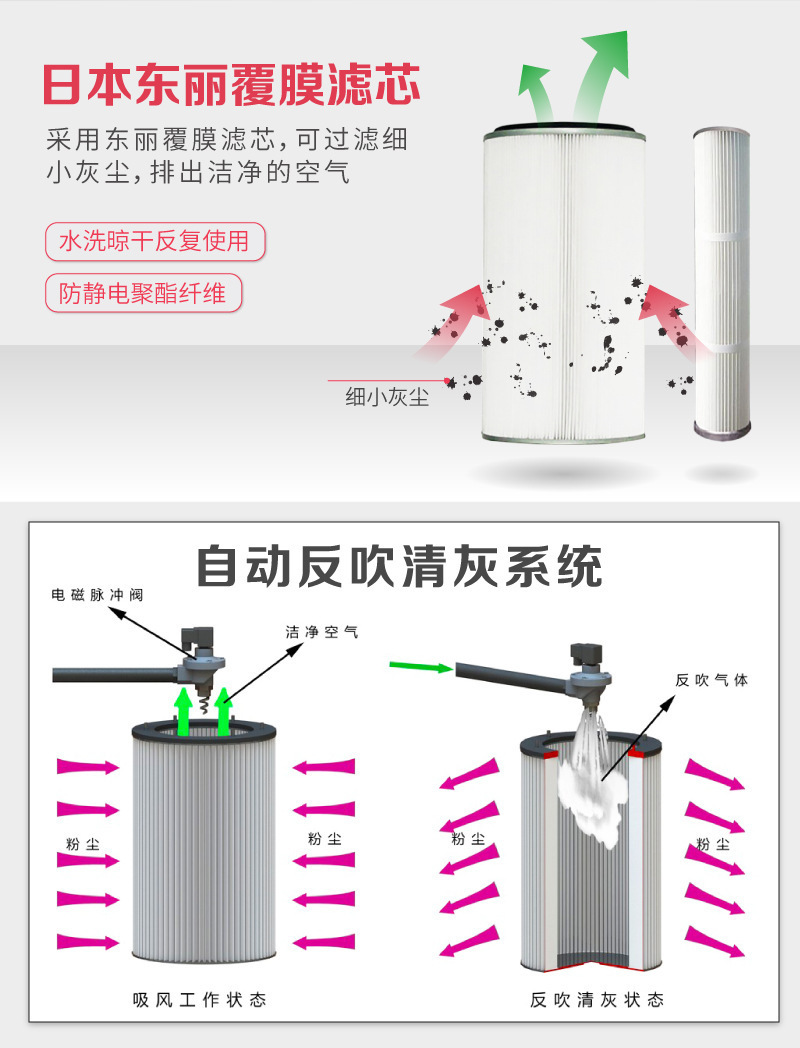

过滤方式:无纺布过滤、滤筒过滤、覆膜滤筒

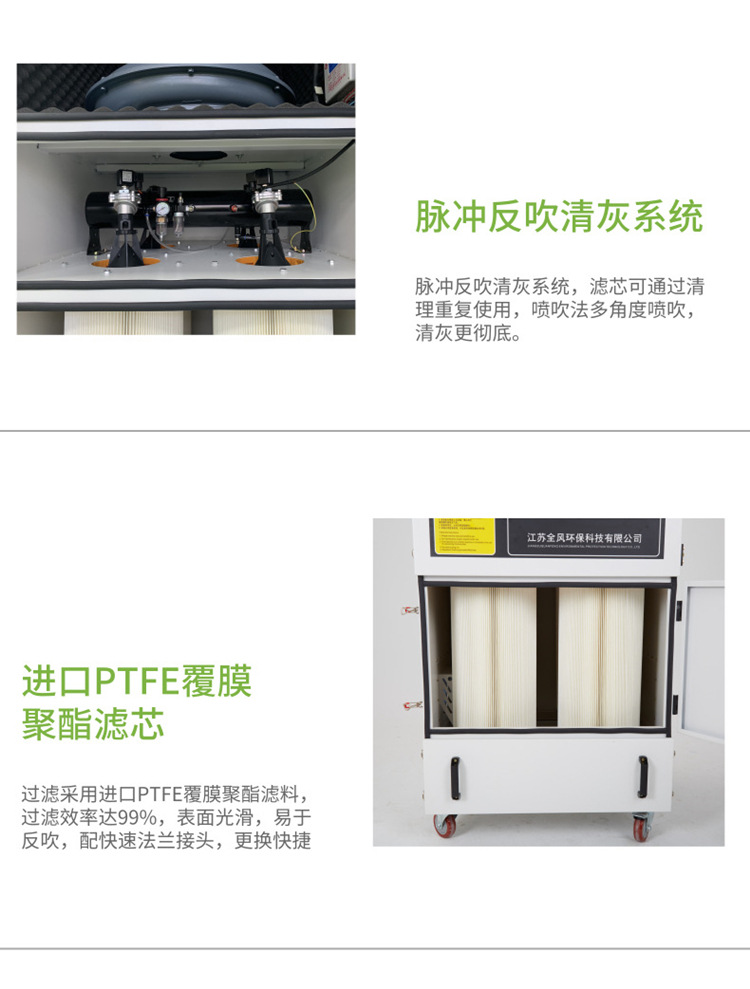

清灰方式:气缸式除尘、手动振尘清灰、电子脉冲除尘等。

噪音: 72 dB ( A )【功率大小变化】

外形尺寸: 500*500*950 、 600*600*150 0 、 800*800*1900 .1000*1000*2000 mm

Widely used in chemical dust collection, workshop environment cleaning, welding waste gas absorption, mixing operations, stone carving operations, machine plate processing operations, grinding operations, metal processing operations, sealing bags, air transport inlet, grinding operations, mixing operations, cutting operations, powder input operations, Mechanical processing, CNC lathe, punch, edM, calender, cutting machine, lens grinding machine and other industrial workshop air purification can be applied.

工业脉冲式布袋除尘器生产厂家 工业集尘器

工业脉冲式布袋除尘器生产厂家 工业集尘器当含尘气体由进风口进入除尘器,碰到进出风口中间的斜板及挡板,气流便转向流入灰斗,同时气流速度放慢,由于惯性作用,使气体中粗颗粒粉尘直接流入灰斗。起预收尘的作用,进入灰斗的气流随后折而向上通过内部装有金属骨架的滤袋粉尘被捕集在滤袋的外表面,净化后的气体进入滤袋室上部清洁室,汇集到出风口排出,含尘气体通过滤袋净化的过程中,随着时间的增加而积附在滤袋上的粉尘越来越多,增加滤袋阻力,致使处理风量逐渐减少,为正常工作,要控制阻力在一定范围内( 140--170毫米水柱),一旦超过范围对滤袋进行清灰,清灰时由脉冲控制仪顺序触发各控制阀开启脉冲阀,气包内的压缩空气由喷吹管各孔经文氏管喷射到各相应的滤袋内,滤袋瞬间急剧膨胀,使积附在滤袋表面的粉尘脱落,滤袋恢复初始状态。清下粉尘落入灰斗,经排灰系统排出机体。由此使积附在滤袋上的粉尘周期地脉冲喷吹清灰,使净化气体正常通过,除尘系统运行。

A common dust collection and cleaning equipment in the production of equipment, the main role of industrial dust collector is to collect the metal dust, dust or scattered materials produced in the production of cleaning and collection, high precision industrial dust collector can also be used to filter and purify air, environmental cleaning, etc. At present, industrial dust collector equipment is an essential cleaning equipment in mechanical parts processing and mold manufacturing.