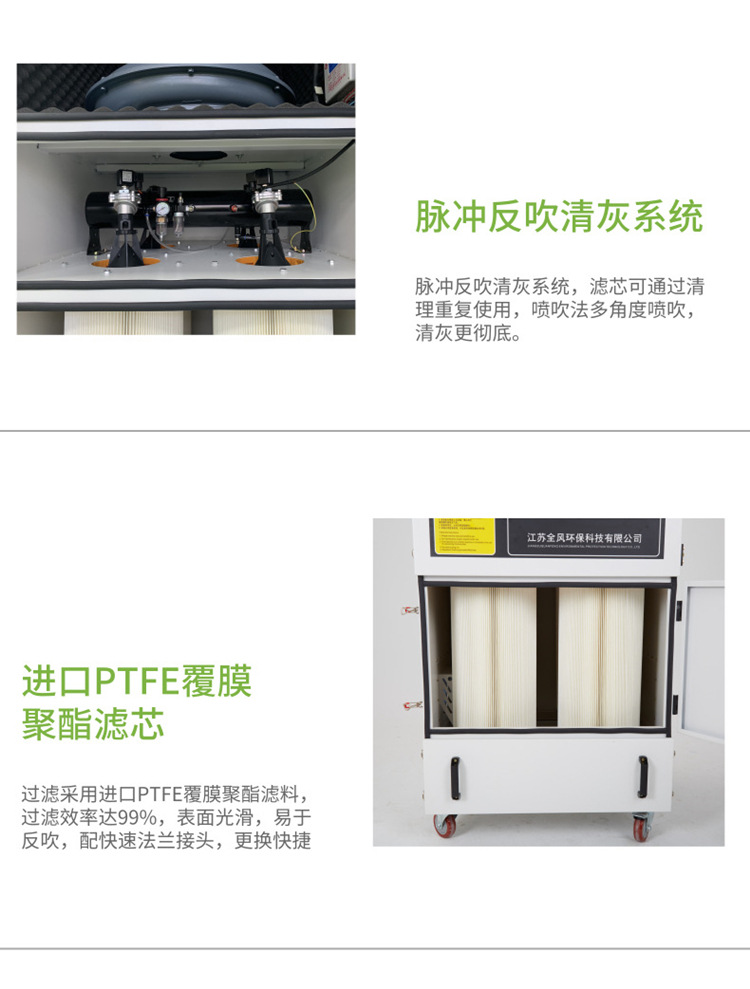

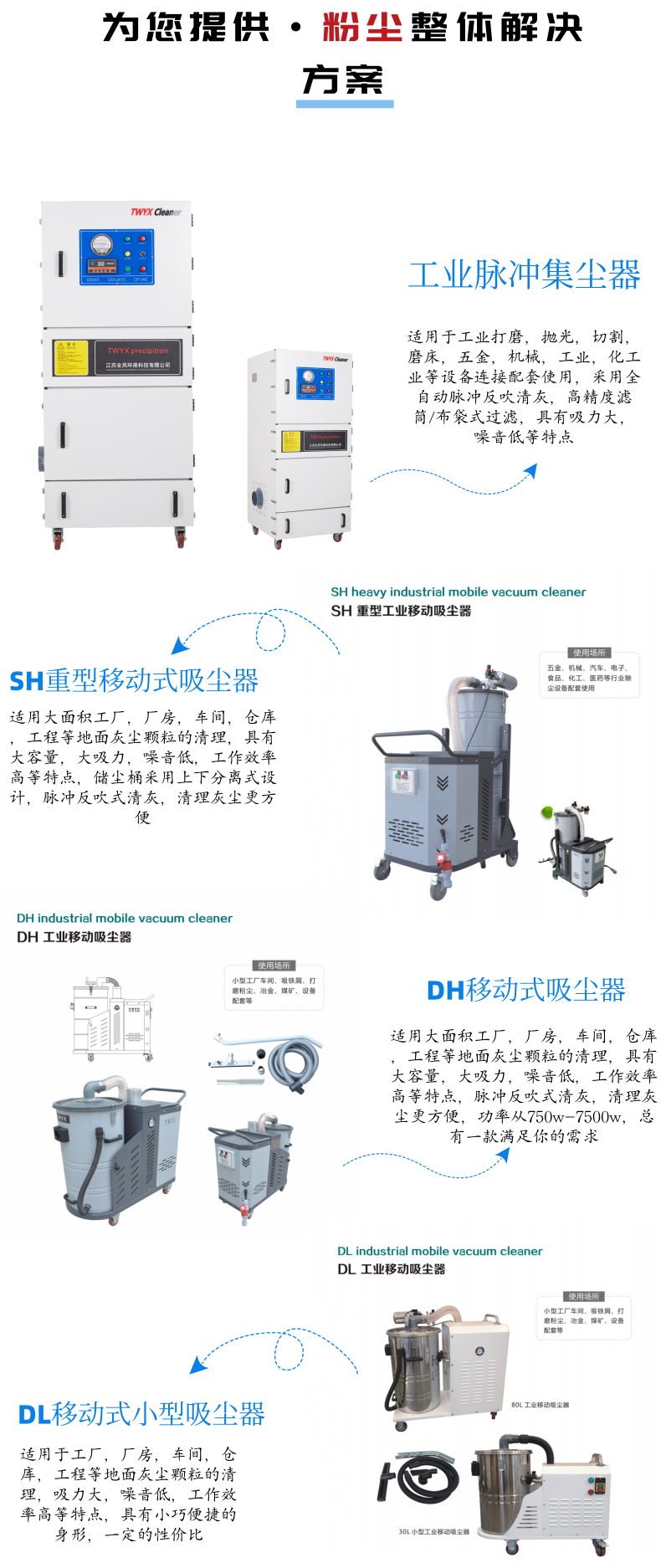

1500脉冲反吹集尘器 特性:

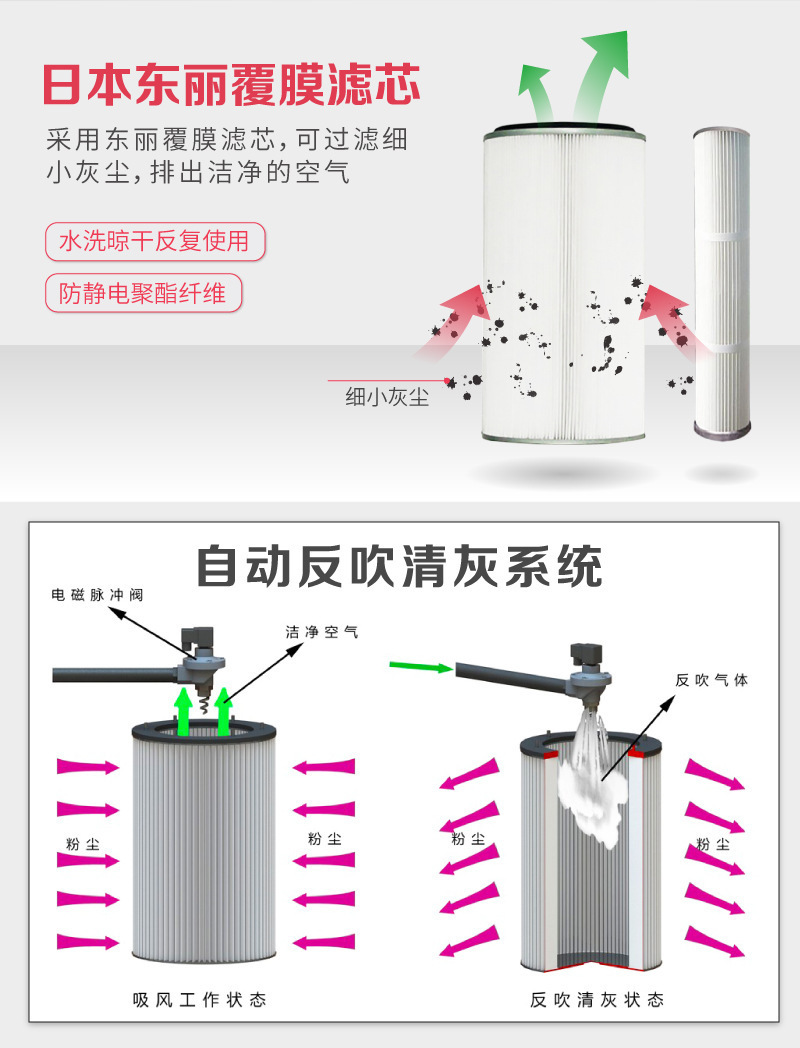

1 、型滤材,亚微米级过滤效率 99% 以上,达标排放

2 、除尘风机,吸力强、风量大、噪音低、、运转平稳

3 、滤袋直立安装,过滤面均匀,停机振打清灰,避免粉尘二次吸附

4 、立柜式机体占地面积小,可加装万向脚轮,增加设备适用性

5 、设备具有过热、短路保护功能,设备运行稳定安全

6 、滤袋组合方便使用成本省,多用于干性大浓度粉尘的收集

7 、适合无压缩气源场合使用,大大增加除尘器适用范围

Fans are widely used in grinding worktable to absorb dust particles, large-area dust collection in workshop, etc; At the same time, it is applied to the on-site collection of dry high concentration dust and crushed materials produced in powder absorption, metallurgy, machinery, building materials, ceramics, plastics, chemical industry, medicine, tobacco and other industries. It is especially suitable for the filtration of fine and fine powder dust produced in the process of crushing, feeding, mixing, filling, metering, loading and other operations, as well as the recovery of precious metal particles and high value-added material dust.

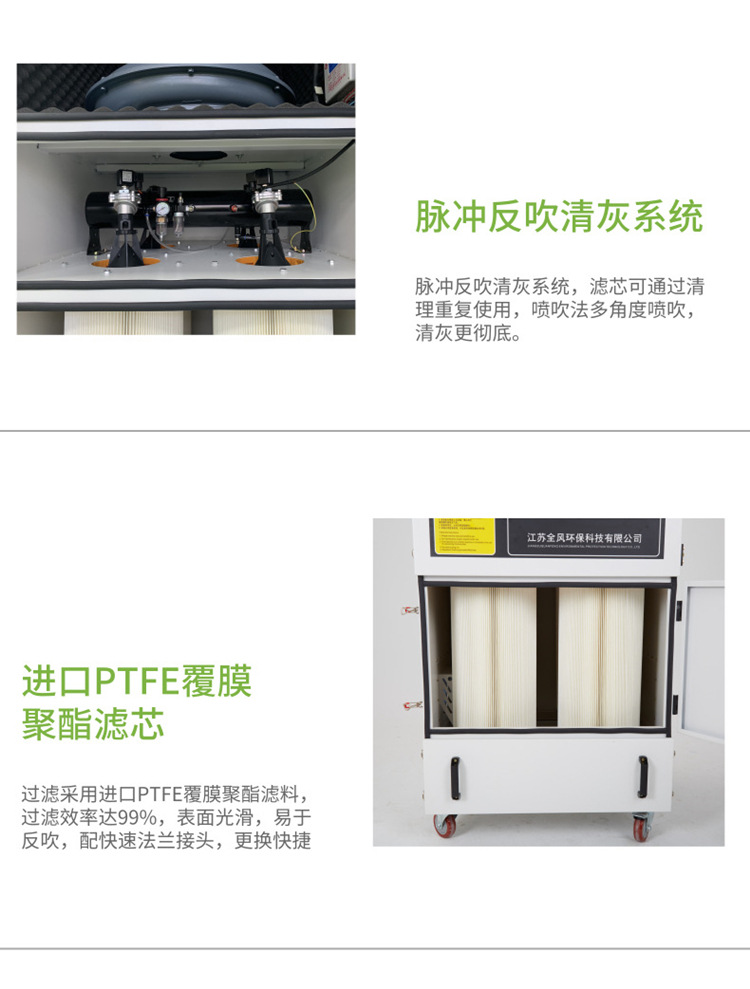

脉冲除尘器操作及说明 :

1、设备在投入使用前应检查设备上的风机运转是否正常,有无异常杂声或不良状况,否则要停机待修。检查电磁脉冲阀是否正常工作,压缩空气是否处于0.5~0.7MPa,否则给予调整。

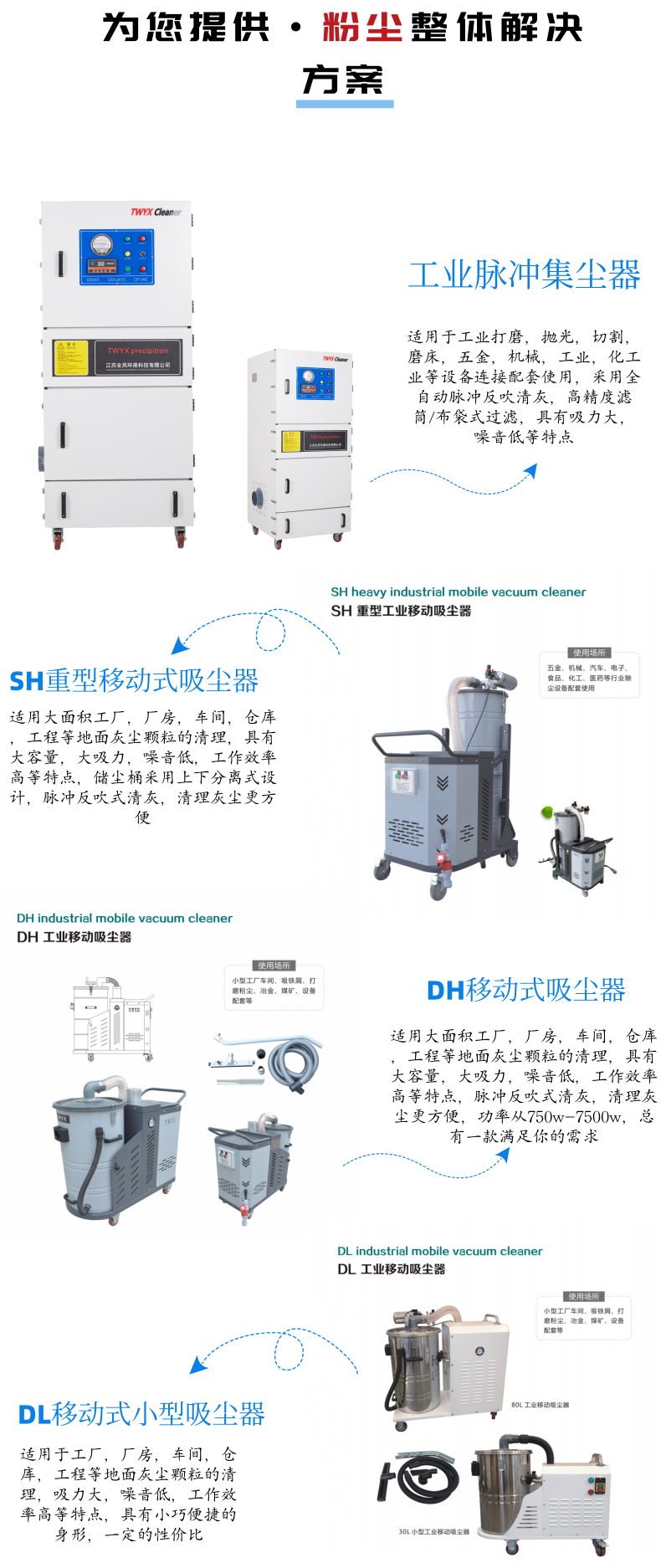

2、脉冲自动清灰的调整。详阅脉冲控制仪使用说明书,调整脉冲间隔、脉冲宽度,脉冲间隔的调整视粉尘量的大小,一般情况可设置在10秒左右,脉冲宽度可设置在0.1秒左右。

3、对贮存在集灰筒的粉尘要定时、定期清理。

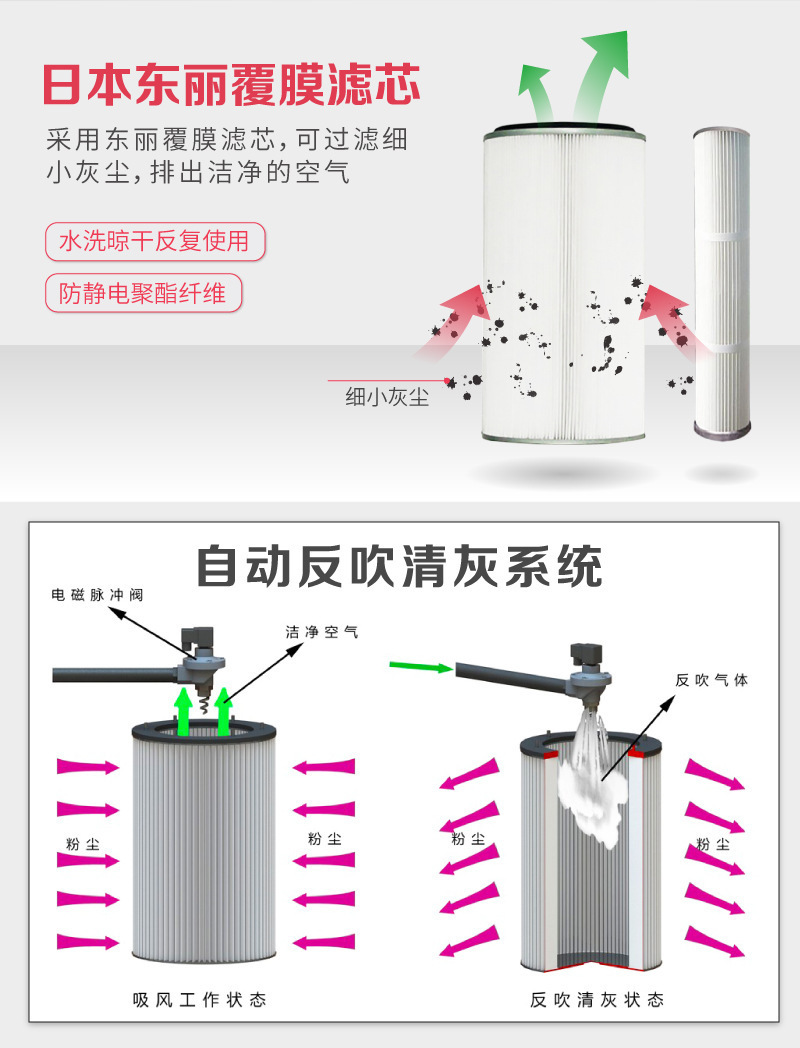

4、设备运行后应对设备的收尘效果进行目测监视,如发现净气出口有明显的粉尘飞出,则说明除尘器内的滤筒有松动或已损坏,应及时检查更换。滤筒要进行半年一次清洗,清洗方法:应将滤筒小心拆下,用清水冲洗干净晾干即可,不得与硬物碰撞,以防划伤滤料,降低收尘效果,滤筒拆卸按“更换方法"进行。

5、设备定期保养,确保正常运行。Design choice configuration of a variety of different material filtering, and a variety of different filtering structure and way, such as HEPA high efficiency filter (minimum can reach 0.01-0.3UM, etc.) or add cyclone separator (for solid-liquid separation) to improve the filtering effect, commercial and household vacuum cleaner filter effect is not the same.

1500脉冲反吹集尘器

1500脉冲反吹集尘器 用户可把设备安装在室内外,大面积的过滤器过滤精度达 0.3微米,有效了周边工作环境清洁,并且排出的风是无油的,是干净的,不会对环境造成二次污染。

结构简单合理,占地面积小,工业吸尘器对吸取物几乎无要求,各类材质、各种形状的废弃介质物都可以吸取,用户可根据其生产工艺、处理风量大小,选择不同的型号的吸尘器。

应用范围: 主要用于机械工业、铸造工业、陶瓷工业、喷沙工业、抛光工业等中的除尘.例如:搅拌作业、粉尘设料作业、机板加工作业、磨沙作业、打磨作业、铸件打磨、清沙作业、切割作业、剪裁作业、破碎作业、石材雕刻作业、钻孔作业。Products can be used to dust density is larger and more metal scraps, casting, grinding, such as lathe, grinding machine, milling machine, grinding machine, polishing machine, carbon powder, pigment, bakelite powder, such as lathe, grinding machine, milling machine, grinding machine, polishing machine, plastic powder and so on, and the proportion of secondary dust, such as cement, ceramic powder, gypsum powder, asbestos powder.